In the world of heavy machinery, precision and durability are paramount. Techniques such as line boring, on-site machining, bore repair, and bore welding play critical roles in maintaining the reliability and longevity of equipment. This article delves into these intricate processes, also exploring related methods like slew milling, xy milling, and bush install.

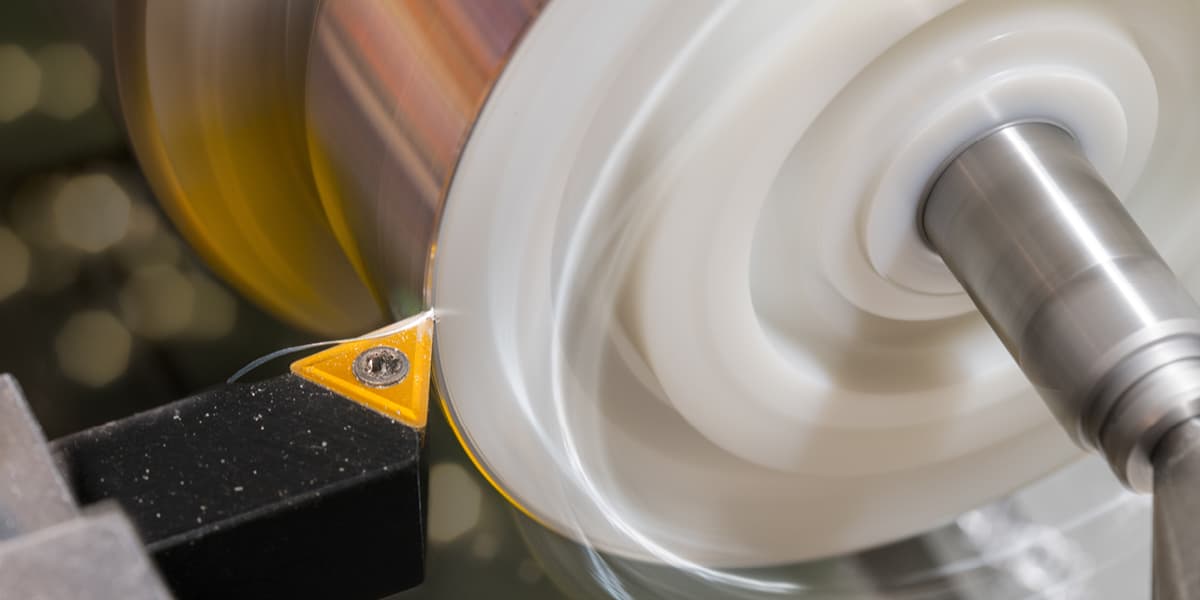

Understanding Line Boring and Its Applications

Line boring involves the accurate enlargement of an already-existing bore. It is a fundamental technique often used to repair worn-out holes or create specific alignments. Achieving high precision in this process ensures that machinery operates smoothly, avoiding unnecessary downtime.

The Process and Benefits of On-Site Machining

On-site machining is a versatile approach to machinery repair that eliminates the need for equipment removal and transport. This practice is efficient, reducing operational interruptions and minimizing costs. Machining activities such as bore repair, which includes bore welding and face welding, can be performed directly at the operation site, ensuring swift and effective maintenance.

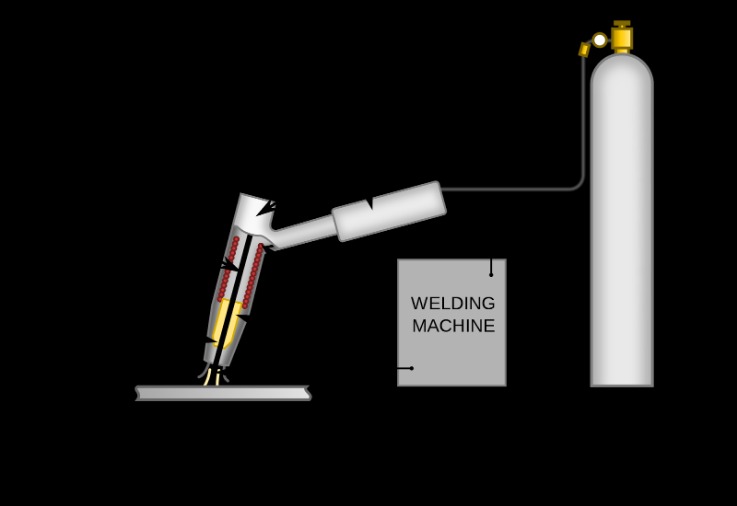

Bore Repair and Welding Techniques

Maintaining the integrity of bores is crucial for the optimal performance of machinery. Bore repair involves resizing and reshaping work, often integrated with allied processes like bore welding. This technique helps restore original dimensions and strength by adding material back to the worn areas before machining them to precise measurements.

Applications of Slew Milling and XY Milling

Slew milling and xy milling are advanced machining techniques used when precision and complex geometries are required. Slew milling is often employed in the manufacturing and refurbishment of gears and large circular components. XY milling, on the other hand, allows for the precise removal of material in both horizontal and vertical planes, ensuring tight tolerances.

Installing Bushings and Performing Face Welding

The bush install process is essential for reducing friction and wear between mechanical parts. Proper installation ensures the longevity of machinery components, reducing maintenance costs over time. Complementing this, face welding restores or enhances surfaces worn out by mechanical interaction, providing a robust solution to extend equipment life.

In conclusion, advanced precision machining techniques such as line boring, on-site machining, bore repair, and bore welding, along with slew milling, xy milling, bush install, and face welding, are vital in the upkeep and enhancement of heavy machinery. Implementing these methods ensures operational efficiency, cost-effectiveness, and extended machinery life, ultimately leading to more sustainable industrial practices.

Read more about bore welding here.