In today’s rapidly advancing industrial landscape, LSR injection molding has emerged as a pivotal technology, driving innovation across various sectors. With its unique properties and versatility, this method is revolutionizing the way products are crafted, offering unparalleled benefits to manufacturers and consumers alike.

Understanding LSR Injection

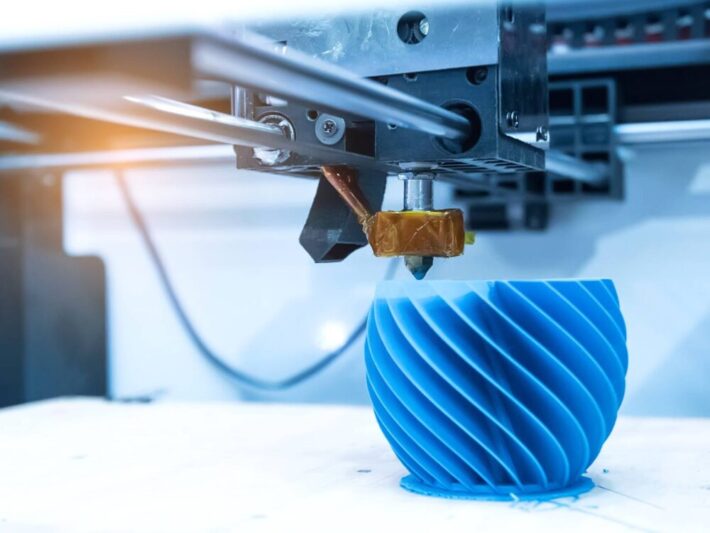

Liquid Silicone Rubber (LSR) injection molding is a process that involves injecting a two-part liquid silicone compound into a heated mold to create durable, flexible products. This technique is particularly renowned for its efficiency and ability to produce high-quality parts with intricate designs and robust performance characteristics.

Key Benefits of LSR Injection

- Precision: The process allows the creation of complex geometries with tight tolerances, essential for products requiring high precision.

- Durability: LSR products demonstrate excellent resilience against extreme temperatures, chemicals, and UV exposure.

- Efficiency: The quick curing times and cycle speeds make LSR injection an economical choice for mass production.

- Biocompatibility: Often utilized in the medical field, LSR is safe and non-toxic, making it ideal for healthcare applications.

Applications Across Industries

The versatility of LSR injection finds applications across an array of industries:

- Healthcare: Used in the manufacturing of medical devices, seals, and gaskets.

- Automotive: Offers outstanding performance in creating seals and electrical connectors.

- Consumer Goods: Utilized for baby products, kitchen utensils, and more, owing to its flexibility and safety.

- Electronics: Provides reliable insulation and protection for electronic components.

Choosing the Right LSR Injection Service

Selecting a reliable service provider is crucial for maximizing the benefits of LSR injection molding. Consider factors like experience, technology used, and service offerings. For those looking for a dependable partner, a detailed overview can be found at LSR injection molding service.

Frequently Asked Questions

What materials can be used in LSR injection molding?

While primarily involving silicone, formulations can be adjusted to meet specific performance requirements, like increased tensile strength or enhanced elasticity.

How does LSR compare to traditional rubber molding?

Unlike traditional methods, LSR injection molding provides superior precision, efficiency, and structural integrity, particularly beneficial for high-volume production runs.

Is LSR suitable for environmentally sensitive applications?

Yes, LSR is inert, hypoallergenic, and generally supports sustainable manufacturing practices, making it apt for environmentally-conscious projects.

In conclusion, the unmatched advantages and wide-ranging applications of LSR injection make it a cornerstone in modern manufacturing, opening doors to innovation and advancement across diverse fields.