Heavy machinery maintenance is an essential aspect of various industries, including construction, mining, and manufacturing. The application of advanced on-site machining techniques has significantly improved the efficiency and effectiveness of these maintenance processes. Among these techniques, Line Boring, bore repair, bore welding, slew milling, xy milling, and bush install are critical for maintaining optimal machine performance.

Comprehensive On-Site Machining Services

The following services are integral to maintaining heavy machinery:

Line Boring

Line boring is crucial for repairing and maintaining cylindrical bores in heavy equipment. This service ensures precise alignment and optimal machine performance by restoring worn-out bores to their original specifications.

Read more about slew milling here.

Bore Repair

Bore repair involves fixing or restoring damaged bores in machinery. Over time, bores can wear out due to constant use and friction. Repairing these bores prevents extensive damage and prolongs the lifespan of the equipment.

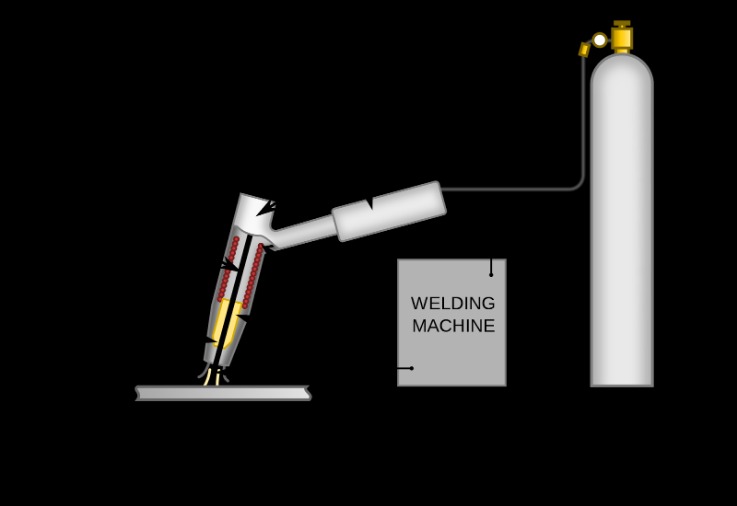

Bore Welding

Bore welding is a process used to repair worn-out bores by adding material to the worn surface and machining it back to its original dimensions. This technique is cost-effective and efficient in extending the life of heavy machinery components.

Slew Milling

Slew milling is used to repair and maintain the slew ring bearing gear teeth of cranes and other large machinery. This process ensures the precise functioning of the slew mechanism, which is vital for the stability and safety of the equipment.

XY Milling

XY milling involves two-dimensional milling to repair or modify machinery surfaces. This method is essential for achieving high accuracy in the flatness and parallelism of critical surfaces in heavy equipment.

Bush Install

Installing bushes (bushings) is necessary to reduce friction and wear between rotating parts of machinery. Proper installation and maintenance of bushes are vital for smooth operation and longevity of moving components.

Face Welding

Face welding involves adding material to the face of a worn component and machining it to the required specifications. This technique is often used to repair and restore critical surfaces, ensuring their functionality and durability.

Benefits of Advanced On-Site Machining

- Minimized Downtime: On-site machining allows for quick repairs without the need to dismantle and transport machinery, significantly reducing downtime.

- Cost Savings: By performing repairs on-site, companies can save on transportation and equipment rental costs.

- Precision and Accuracy: Advanced machining techniques ensure high precision and alignment, enhancing machine performance and reliability.

- Extended Equipment Lifespan: Regular maintenance and repairs extend the operational life of heavy machinery, reducing the need for frequent replacements.

Frequently Asked Questions (FAQs)

What is line boring, and why is it important?

Line boring is a machining process that repairs and maintains cylindrical bores. It ensures precise alignment and optimal machine performance by restoring worn-out bores to their original specifications.

How does bore welding differ from bore repair?

Bore welding involves adding material to a worn bore surface and machining it back to its original dimensions, while bore repair typically refers to fixing damaged bores without adding material. Both techniques aim to restore the functionality of the bore.

Why is slew milling essential for heavy machinery?

Slew milling repairs and maintains the slew ring bearing gear teeth, ensuring the precise functioning of the slew mechanism. This process is vital for the stability and safety of cranes and other large machinery.

What is the significance of bush install in machinery maintenance?

Installing bushes reduces friction and wear between rotating parts, ensuring smooth operation and longevity of moving components. Proper bush installation and maintenance are crucial for optimal machine performance.

When should face welding be used?

Face welding should be used when critical surfaces in machinery become worn and need to be restored to their original specifications. Adding and machining material ensures the durability and functionality of these surfaces.

Conclusion

Employing advanced on-site machining techniques like line boring, bore repair, bore welding, slew milling, xy milling, bush install, and face welding is essential for maintaining the efficiency and longevity of heavy machinery. These services not only minimize downtime and save costs but also ensure the precise functioning and extended lifespan of critical equipment. Investing in these advanced techniques is a proactive approach to machinery maintenance that benefits industries reliant on heavy equipment.